The best choice for window profile manufacturers with their own mixer lines.

The non-laminated parts of a laminated window profile are only exposed to direct weathering rarely, and only when the window is tilted or opened in the immediate field of vision. Therefore, the issue of economy is all the more important with the coloring of base PVC window profiles. It is necessary to make a manageable range of two to three house colors in a particularly economical, efficient and reproducible way. With customer-specific, speck-free precolor® pigment preparations which match the requisite shade of color optimally and guarantee the perfect result.

Exactly as much quality as necessary.

In comparison with masterbatches, powder pigment preparations are the most economical form of PVC profile coloring. That’s because in this area, we are able to offer a wide range of exact shades here with low application concentrations according to RAL or CSTB standards if required. In general, two to three house colors are used per manufacturer, such as caramel, brown and anthracite. The powder pigment mixture can be fed directly into the heating mixer without costly pre-dispersion.

Another advantage: Unlike the coloring of window profiles with masterbatches, pure pigment mixtures do not require a separate plastic support material. This means that side effects on the rheological properties are avoided, as the pigment and PVC can be processed together in an exceptionally efficient way.

”100 percent pure pigment is a particularly economical alternative to PVC coloring with masterbatches.“

Carsten HerrmannDeputy Head of Marketing & Sales

Laminate adhesion – a frequently underestimated problem.

The adhesive characteristics of the laminate can be impaired if substances migrate from the polymer surface and the adhesion between the hard PVC and the laminate decreases. This is an effect which isn’t just disadvantageous from the visual perspective, but also in terms of the protective function, and which must be prevented. Migrating substances can build up a separating layer between the laminate and window profile. In the worst case scenario, the adhesion can be reduced in such a way that the laminate detaches completely.

It is therefore all the more important to place special emphasis on the migration properties of the components involved as soon as the colorant is designed.

Line purity and the latest mill technology as the key to a streak-free result.

On the basis of our experience in the selection of pigments and our state-of-the-art milling and mixing technologies, we are able to make exceptionally homogeneous preparations that are free of specks or other impurities. Thanks to so-called line purity tests, we are able to prevent streaks or inclusions on the surface of the profile. Contaminations in the colorant and therefore in the system are prevented by the regular wet cleaning of our systems technology.

Completely dust-free handling with s-Packs.

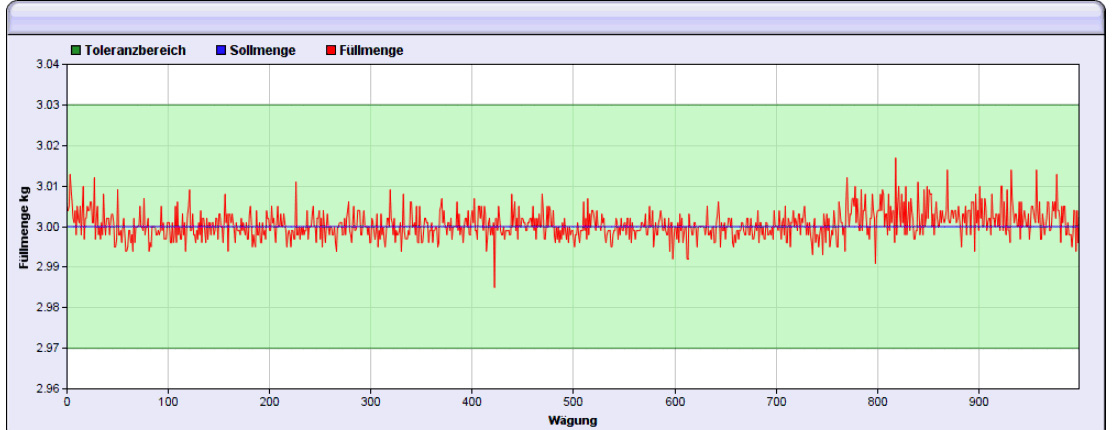

Documented precision: Extract from the weighing log of an s-Pack.

To optimize the exceptionally dust-intensive handling of pure powder pigments, we have developed a precisely pre-dosed packaging solution which can be fed directly into the heating mixer, dissolves there without residue and releases the pure pigment. In a fully documented weighing process, the individually composed pigment powders are dosed precisely according to the formulation and the minimum tolerances. On the one hand, this ensures the reproducibility, and on the other, compliance with the desired shade of color. An absolutely clean solution.

Your personal contact: Carsten Herrmann

Do you have any further questions about the coloring of laminated PVC window profiles, or would you like to start a project with us? We’re happy to help.

Phone +49 9232 9945-46

Mobil +49 172 7905845

E-mail carsten.herrmann@farbenwerke.de